Engineering That Thinks Beyond the Drawing Board

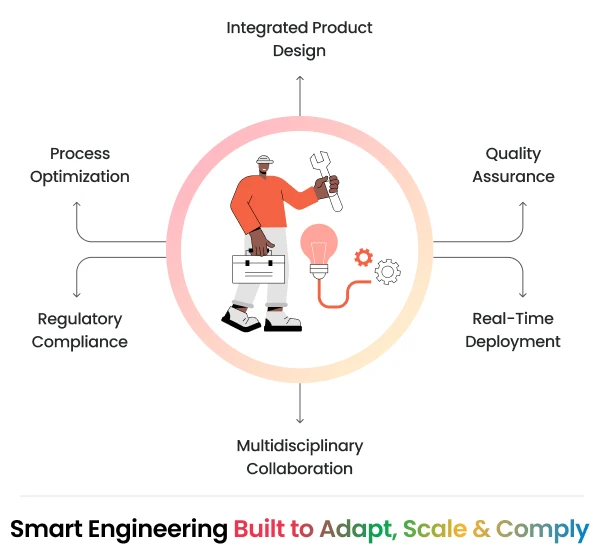

Engineering today goes far beyond precision drawings and clean code. It demands agility in execution, compliance built into every stage, and innovation that scales from design to deployment. At CTC, we unite expertise across mechanical, electrical, civil, software, and systems engineering to solve design, process, and manufacturing challenges that don’t fit in a box. Whether it’s prototyping a new device, validating complex systems, or meeting regulatory milestones, we work end-to-end, without compromising speed, quality, or safety.

Our strength lies in depth and diversity. From smart medical devices and next-gen automotive components to high-performance infrastructure and industrial systems, we support product and process development across tightly regulated, mission-critical environments. With specialists in every discipline — and cross-functional collaboration at the core — we help you build what’s next, with engineering that adapts, integrates, and performs where it matters most.

Strategic Pillars of Our Engineering Services

- Integrated Product Design & Development – From early-stage design to prototype engineering, we create scalable, compliant, and performance-driven product architectures across mechanical, electrical, and software layers.

- Manufacturing Process Optimization – Our experts streamline and enhance manufacturing workflows with process engineering, production scalability, lean manufacturing, and digital twin modeling.

- Engineering Compliance & Quality Oversight – With deep expertise in regulatory frameworks and quality protocols, we ensure products meet international standards, pass audits, and stay ready for market entry.

Service Offerings

Product Design & Prototyping

Multi-domain CAD modeling, simulation, digital prototyping, and BOM generation using industry-leading tools for fast-track product development.

Manufacturing Engineering Support

Design for Manufacturability (DFM), tooling optimization, production planning, and continuous process improvement for high-yield operations.

Quality & Regulatory Engineering

Defect analysis, compliance documentation, root-cause investigation, validation protocols, and support for ISO, ASME, FDA, and global standards.

Systems Engineering

End-to-end systems integration, embedded development, control systems, and cross-platform connectivity for complex, interoperable solutions.

Field & Maintenance Engineering

On-site diagnostics, technical support, and maintenance planning for deployed assets and critical field infrastructure.

Materials & Process Innovation

Advanced materials research, stress/strain analysis, thermal simulations, and process optimization for performance and sustainability.

Real-World Impact

Faster Product Realization

Integrated design and development reduce time-to-market across industries.

Lower Operational Costs

Optimized manufacturing and reduced engineering rework translate to tangible cost savings.

Greater Design Integrity

Cross-domain collaboration improves reliability, safety, and performance.

Simplified Compliance

Our engineering workflows align with global regulatory frameworks, ensuring smooth approvals.

Scalable Resource Support

From one-time consulting to ongoing project teams — scale your engineering talent when and where you need it.

Why Choose CTC for Engineering?

Multi-Disciplinary Expertise

Our engineers bring cross-functional knowledge across design, systems, quality, and field engineering.

Tool-Agnostic & Tech-Driven

We work with your preferred software environments or recommend the right stack based on your project’s complexity.

Built for Speed & Precision

Our agile engineering teams adapt fast — without compromising accuracy or compliance.

Project Ownership Mindset

From concept to delivery, we take accountability — ensuring every detail meets your standards.